REMOTE CONTROLLED VEHICLE

For a closer look at the project, download our final paper here:

Sept-Nov 2015

Team of 3

Major Design Components

Overview of the Project

Personal Contributions

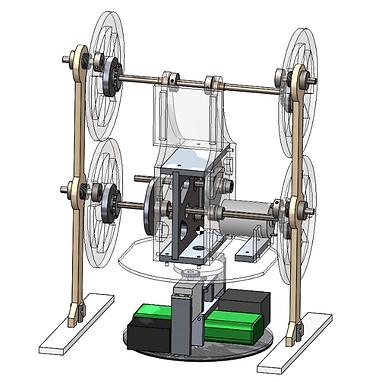

For this project, part of our Machine Engineering class, we built a remote controlled vehicle designed to complete an obstacle course within 5 minutes. Design limitations included walking for transportation and a specific list of materials that could be used. All of the parts were hand machined by members of the group.

Our design was centered around the maze, an obstacle in the course that, at only 10 inches wide, required precise turning. We developed a spinning chassis that, when the legs were lifted off the ground allowed for rotation in any direction. We also focused on simplicity, keeping the design to under 40 machined parts.

I took on a large portion of the decision matrices, as well as designing and machining the gearbox. This involved finding the gear ratio required for our load, and iterating on the configuration to create the most compact and stable version possible.

Check out the slide deck below for more information about the design.

I also kept a personal design journal that documents the entire process. It's too large to upload here, but if you're interested in checking it out, send me a message and I'll see what I can do.